Tuesday, December 28, 2010

Work in the shop has been slow but steady of late. I've been on a little string of bad luck lately--a couple weeks ago I was in a bike accident on my way to work and hurt my shoulder, which made banjo work difficult, and I've been pretty ill for the past few days, so had to miss more opportunities to work. But fear not, if you have a banjo on order, I am working on it right now, and making quick progress!

Monday, December 27, 2010

Saturday, December 25, 2010

Wednesday, December 15, 2010

Saturday, December 11, 2010

Wednesday, November 24, 2010

Wednesday, September 29, 2010

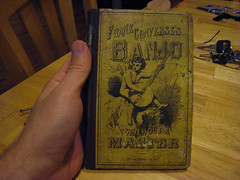

I recently had the good fortune to pick up an original edition of Frank Converse's Banjo without a master. Authored by Converse, then a renowned banjo player and performer, this nice little book, published in 1865, represents one of the earliest popularly available banjo tutors. It contains an extensive slice of the minstrel repertoire, with highly detailed, measure-by-measure instructions on how to play each tune.

Sunday, August 29, 2010

Well, I have just about finished Lloyd's giant gourd banjo. After stringing it up and playing it this evening, which concludes several weeks of work, I think I can safely say that it is the finest sounding gourd banjo I have yet produced. Of course, I think that to be the case every time I finish any banjo, but it seems particularly true at the moment.

There are certain key structural differences that are working together to give this banjo a massive, deep, and full-blasting growl of a tone. First, the size. Lloyd wanted the neck to have a 28" scale to match the giant 14" pot tackhead I keep at home. Longer scale necessitates higher string tension, the end product of which is greater sustain and a richer (in my opinion) tone.

Second: the gourd. The gourd I used for this project came from Paul Sedgewick's shop. In the first place, it is gigantic, being about 13 inches in diameter. Another interesting thing is that it is also very thin. So thin, in fact, that I had to reinforce it with an epoxy resin. The resin coated the interior of the gourd, creating what is essentially one big resonator. Frequencies that would have been previously absorbed by the sound-deadening, soft, rough interior of the gourd are now projected with great clarity.

There are certain key structural differences that are working together to give this banjo a massive, deep, and full-blasting growl of a tone. First, the size. Lloyd wanted the neck to have a 28" scale to match the giant 14" pot tackhead I keep at home. Longer scale necessitates higher string tension, the end product of which is greater sustain and a richer (in my opinion) tone.

Second: the gourd. The gourd I used for this project came from Paul Sedgewick's shop. In the first place, it is gigantic, being about 13 inches in diameter. Another interesting thing is that it is also very thin. So thin, in fact, that I had to reinforce it with an epoxy resin. The resin coated the interior of the gourd, creating what is essentially one big resonator. Frequencies that would have been previously absorbed by the sound-deadening, soft, rough interior of the gourd are now projected with great clarity.

Saturday, August 21, 2010

The most tedious part of building a gourd banjo (the way I do it), comes in creating the fit between the heel of the neck and the gourd, with its multiples asymmetries.

Here is a photo of the banjo I'm working on right now, the fit for which is around 95% after 3.5 hours of work:

The heel:

A jumbo canteen gourd that I just reinforced with a two-part epoxy resin:

Here is a photo of the banjo I'm working on right now, the fit for which is around 95% after 3.5 hours of work:

The heel:

A jumbo canteen gourd that I just reinforced with a two-part epoxy resin:

Friday, August 13, 2010

walnut, cherry, and sugar maple: great ice cream flavors on their own, but also my favorite hardwoods. i've got a number of full sized billets of each headed here to my shop, as well as red and white oak, hickory, and butternut (i swear i dont pick my materials based on what sort of imaginary desserts they would make). they are all coming from sustainable, independent sources in wisconsin, indiana, and pennsylvania. i am particularly excited about the lumber on it way from pennsylvania, which is coming from a small milling operation that i have never worked with before.

after the stock of exotic hardwoods i have runs out, i am gong to make a concerted effort to only build with native species. even though its already too late to save the planet, i have reservations about the supply lines for some of the fancier african and asian hardwoods, regardless of claims that they have been harvested in accordance with CITES.

after the stock of exotic hardwoods i have runs out, i am gong to make a concerted effort to only build with native species. even though its already too late to save the planet, i have reservations about the supply lines for some of the fancier african and asian hardwoods, regardless of claims that they have been harvested in accordance with CITES.

Saturday, August 07, 2010

Things have been very busy in the shop this summer, with multiple banjos on my bench for the past several months. The upcoming months will be no different: I will have completed Stichter and Boucher copies, along with several other custom orders. In addition, I am happy to say that I am working with a very talented designer to completely overhaul the website. Aside from a new layout, there will be an expanded audio-visual section with new video and audio recordings, a better, more functional gallery, new text, and an all-around cleaner, richer visual experience for visitors. Keep a eye out for the new site to be rolled out in the next couple months.

Thursday, July 29, 2010

Thursday, July 22, 2010

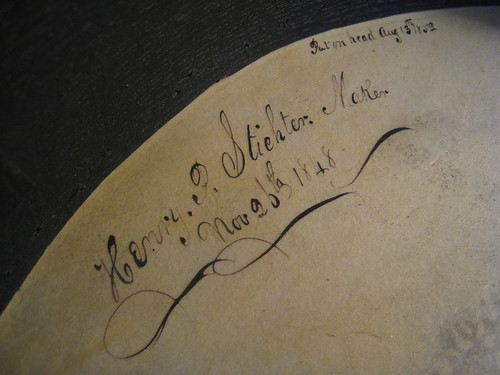

I had the distinct pleasure of visiting Jim Bollman and his extraordinary collection of banjos and banjo-related ephemera last night. It was a fantastic experience, and I hope to return often. The purpose of my visit was, ostensibly, to visit one instrument in particular—the ca. 1848 Henry Stichter banjo, which I am currently working to reproduce. The banjo itself was built by Stichter when he was just 16 years old, and the features of its construction are marvelous and bizarre.

The banjo originally had two drone strings—one on each side of the neck—but one has since been removed, leaving the more familiar 5-string construction intact. The oak rim itself, which is enormous, is only 3/16” thick, and joined only to a radiused block of wood by way of four screws, rather than the scarf joint that is more typical of a single-ply rim from that era. The numerous quirks represent a challenge where reproduction is concerned: should a copy be 100% faithful, the banjo itself would be difficult to play and feature modes of construction that would make it a somewhat undesirable option where durability is concerned. Thus, the challenge in this project is to strike a balance between modern standards of playability and an adherence to the original design and overall aesthetic. In short, this banjo would be faithful in appearance to the original but far more playable and a lot more sturdy. It should be done some time in September. Keep an eye out.

In the mean time, I am working on a number of interesting custom projects to be completed in the coming weeks.

The banjo originally had two drone strings—one on each side of the neck—but one has since been removed, leaving the more familiar 5-string construction intact. The oak rim itself, which is enormous, is only 3/16” thick, and joined only to a radiused block of wood by way of four screws, rather than the scarf joint that is more typical of a single-ply rim from that era. The numerous quirks represent a challenge where reproduction is concerned: should a copy be 100% faithful, the banjo itself would be difficult to play and feature modes of construction that would make it a somewhat undesirable option where durability is concerned. Thus, the challenge in this project is to strike a balance between modern standards of playability and an adherence to the original design and overall aesthetic. In short, this banjo would be faithful in appearance to the original but far more playable and a lot more sturdy. It should be done some time in September. Keep an eye out.

In the mean time, I am working on a number of interesting custom projects to be completed in the coming weeks.

Monday, July 12, 2010

If you're feeling lucky, you can head over to the banjo hangout and enter to win the banjo pictured here (click for full size):

I built this instrument specifically for the banjohangout. It's a great site worthy of your support if you are at all interested in the banjo, so check it out.

I built this instrument specifically for the banjohangout. It's a great site worthy of your support if you are at all interested in the banjo, so check it out.

Wednesday, March 17, 2010

My workshop is once again located on dry land, and I only had to stay up until 4AM pumping water out of the basement twice in a row. Tomorrow I will have to put the whole shop back together (not the easiest task), and production should be up and running by Friday.

On an unrelated note, the cost of tool black is appallingly high. Oh, the price we are willing to pay to make new things look old. . .

On an unrelated note, the cost of tool black is appallingly high. Oh, the price we are willing to pay to make new things look old. . .

Sunday, March 14, 2010

New England is being obliterated by a massive nor'easter right now. High winds and some of the most incredible flooding I've ever seen in this area. The real problem for me, though, is that my workshop is currently flooded out. I had to tear it apart at high speed to save my tools and supplies from water. It'll be a bit before I can rebuild it.

Thursday, February 25, 2010

I made this banjo for mark a couple years ago. It was a pleasure to build and a joy to play. I hated to put it in the mail, but I'm glad to see it found such a happy home.

Find more videos like this on Minstrel Banjo

Find more videos like this on Minstrel Banjo

Thursday, February 11, 2010

Sunday, February 07, 2010

Tuesday, February 02, 2010

Wednesday, January 20, 2010

Tuesday, January 05, 2010

Subscribe to:

Comments (Atom)